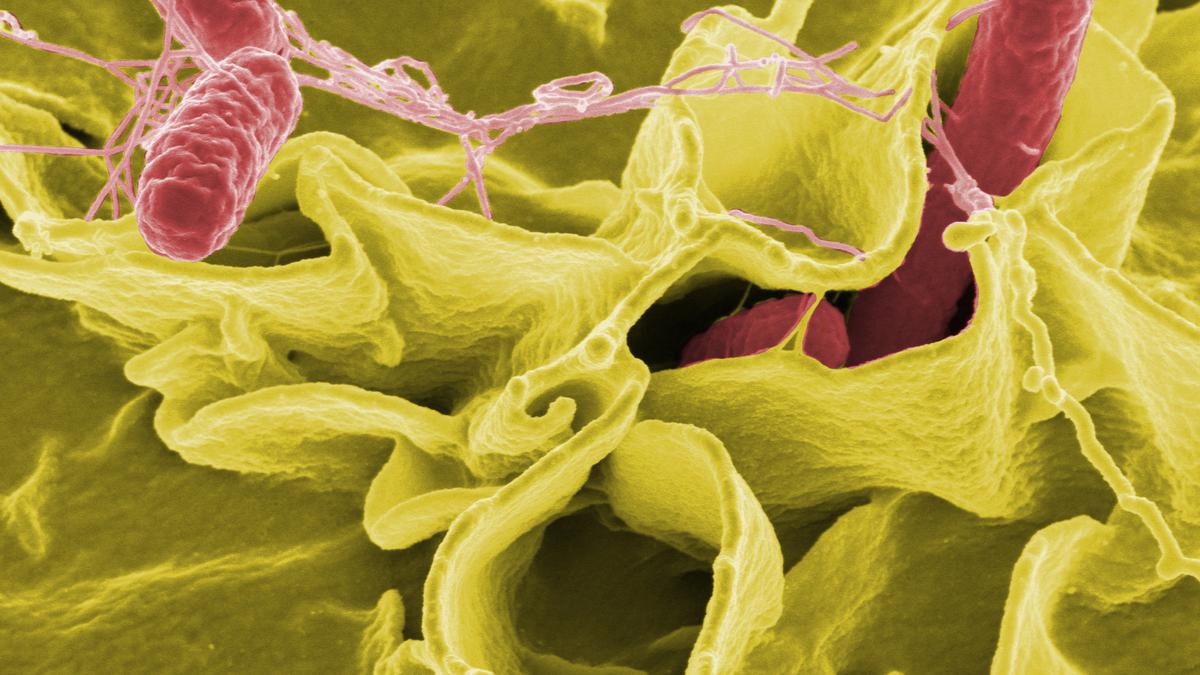

(left to right) Daniel Tan- Managing Director Hunting Energy Services Pte. Ltd (Asia Pacific), Jim Johnson- CEO Hunting PLC, PR Jindal- Chairman Jindal SAW Ltd. and Neeraj Kumar- Group CEO & Whole -Time Director, Jindal SAW Ltd inaugurate a facility of JV firm Jindal Hunting Energy Services Ltd (JHESL) in Nashik, on September 18, 2023.

| Photo Credit: PTI

Jindal Hunting Energy Services Ltd, a 51:49 joint venture of Jindal SAW Ltd and Hunting Energy Services Pte Ltd has set up India’s first facility for producing and supplying pipes, tubes, and premium connections to the Oil Country Tubular Goods (OCTG) market.

The partners have invested ₹200 crore to establish this facility which will replace imports estimated at $200 million per annum.

Thus far, products for this market had to be imported from other countries, putting a strain on the foreign exchange situation in India.

This facility not only supports Indian Oil & Gas industry but also will have huge export potential thereby earning valuable foreign exchange for the country.

The facility has come up inside Jindal SAW’s unit at Nashik.

P.R. Jindal, Chairman, Jindal SAW Ltd. said with this initiative the group will be able to participate in the AatmaNirbhar initiative of the Government of India.

The facility is envisioned as a ‘Center of Excellence’, a unique establishment in this region, offering a comprehensive array of products and services within the OCTG sector of the Oil & Gas industry.

The facility will be threading Hunting’s premium connections, ranging from 2-3/8” to 20”, and providing Large O.D. Welded Connectors, spanning from 20” to 36”.

This comprehensive range encompasses various grades in iron & steel, as well as alloy steel & exotic value-added grades.

Jim Johnson, CEO, Hunting PLC said, “Today, both Jindal SAW and Hunting make history, with the opening of the JV’s full-fledged premium OCTG, accessories and manufacturing operations, in support of the Government’s “Make in India” initiative.”

“Hunting will work alongside Jindal SAW to provide the highest standards in quality and services in delivering the best premium OCTG and accessories to our valued customers in India and also abroad. We look forward to introducing more advanced Connection Technology as we progress along,” he said.

“I am confident that this JV manufacturing hub will bring benefits to local O&G industry, and also play a part in India’s energy transition,” he added.

The facility is set to achieve an annual threading capacity of 70,000 metric tons of OCTG. It will be fully supported by a seamless supply chain, drawing raw materials and inputs from the Jindal SAW facility in Nashik and other locations across the country.

This advanced facility boasts cutting-edge equipment, on par with the best globally, featuring a high degree of automation and sophisticated testing capabilities to guarantee top-quality products that meet the rigorous demands of the oil & gas sector.

Daniel Tan, MD, Hunting Asia Pacific Segment said, “Both JSAW and Hunting have come a long way, starting from sharing an idea in forging a strategic alliance and finally to a fully-fledged JV manufacturing hub for premium OCTG and accessories, built from greenfield.”

“With the JV manufacturing hun built next to Jindal SAW seamless pipe mill, and with easy access to Mumbai port, we provide world-class premium OCTG not only to the rapid growing domestic market in India, but also serve as an important Gateway to the Middle East and Africa market,” he said.

“The JV manufactring hub is truly a one stop shop for premium OCTG and accessories for both domestic and international customers,” he added.

(This writer was in Nashik at the invitation of the company.)